PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer that has become a popular material in a wide range of industries due to its unique properties, such as high chemical resistance, non-stick surface, and low coefficient of friction. Modified PTFE, also known as MPTFE and TFM, is a chemically modified version of PTFE that offers higher performance.

In this blog post, we will explore what modified PTFE is, its benefits, the regular grades available, and how to find a reliable supplier.

What Is Modified PTFE?

Modified PTFE can be considered a second-generation PTFE. It is a tetrafluoroethylene-based copolymer that incorporates a small amount (less than 1%) of perfluorinated modifier (PPVE) into its molecular structure. It’s greatly improved on the performance of standard PTFE, which has a higher permeation resistance, lower creep and smoother surface.

The modified chemical structure of the polymer allows us to distinguish between Standard PTFE and modified PTFE. The molecular weight of Modified PTFE is one-fifth that of Standard PTFE. This means that the PTFE particles fuse better, thus significantly contributing to a better weldability of components made of Modified PTFE.

The relatively low molecular weight of Modified PTFE would normally give rise to an end product with higher crystallinity and hence lower mechanical properties. However, the perfluoropropyl vinylether (PPVE) modifier in Modified PTFE specifically inhibits crystallization, thus increasing the amorphous content while maintaining the preferred mechanical properties of Standard PTFE. In addition, the modifier ensures better distribution of the crystallites in the amorphous matrix and dramatically reduces cold flow.

Benefits

Modified PTFE exhibits the typically positive properties of standard PTFE, such as excellent chemical resistance and thermal stability. Additionally, has the following advantages:

- Substantially lower deformation under load

- Part surfaces are smoother and less porous – components stay clean since they are less likely to trap contaminants

- Longer flex life than PTFE

- Improved weldability

- Lower permeability

- Higher transparency

- Better compression stress relaxation, particularly at elevated temperatures

Highlights of the Modified PTFE properties advantage

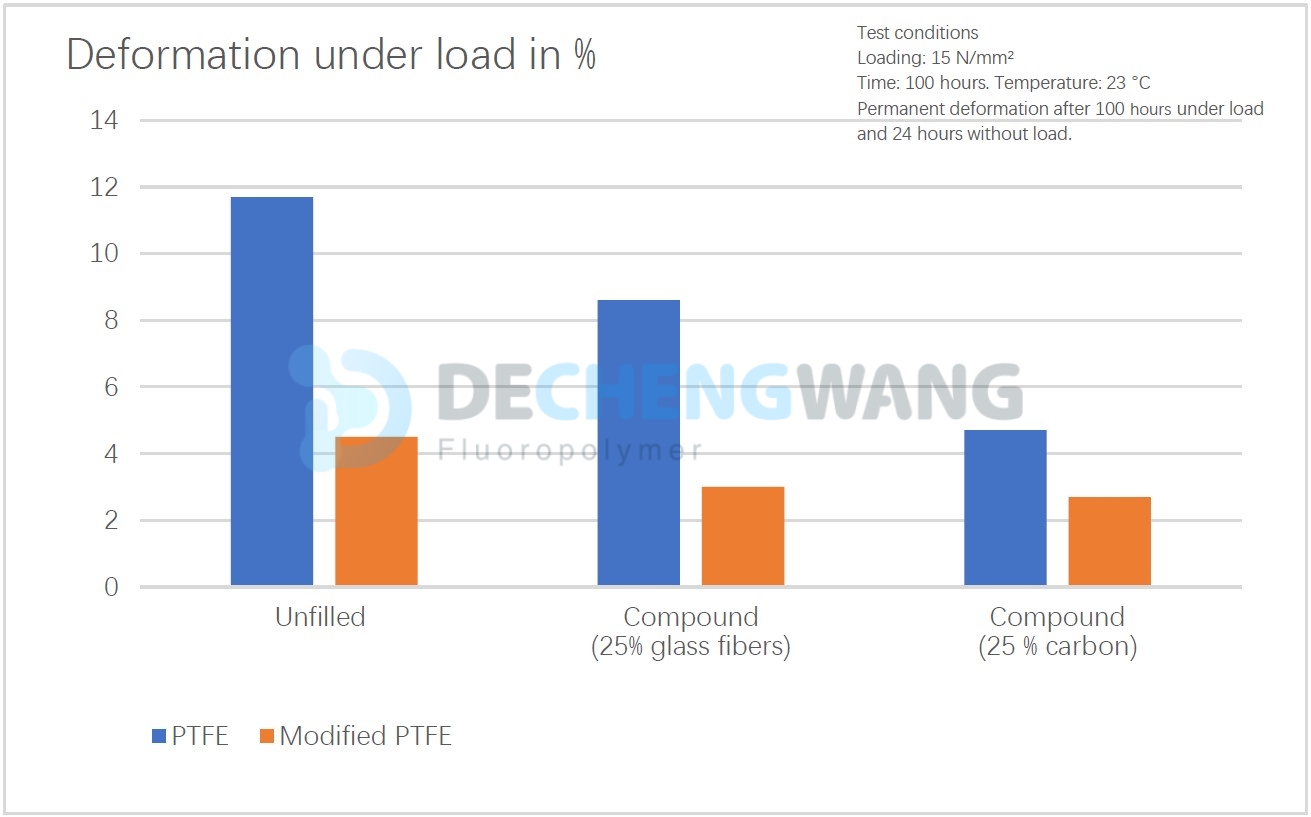

Low Deformation under load

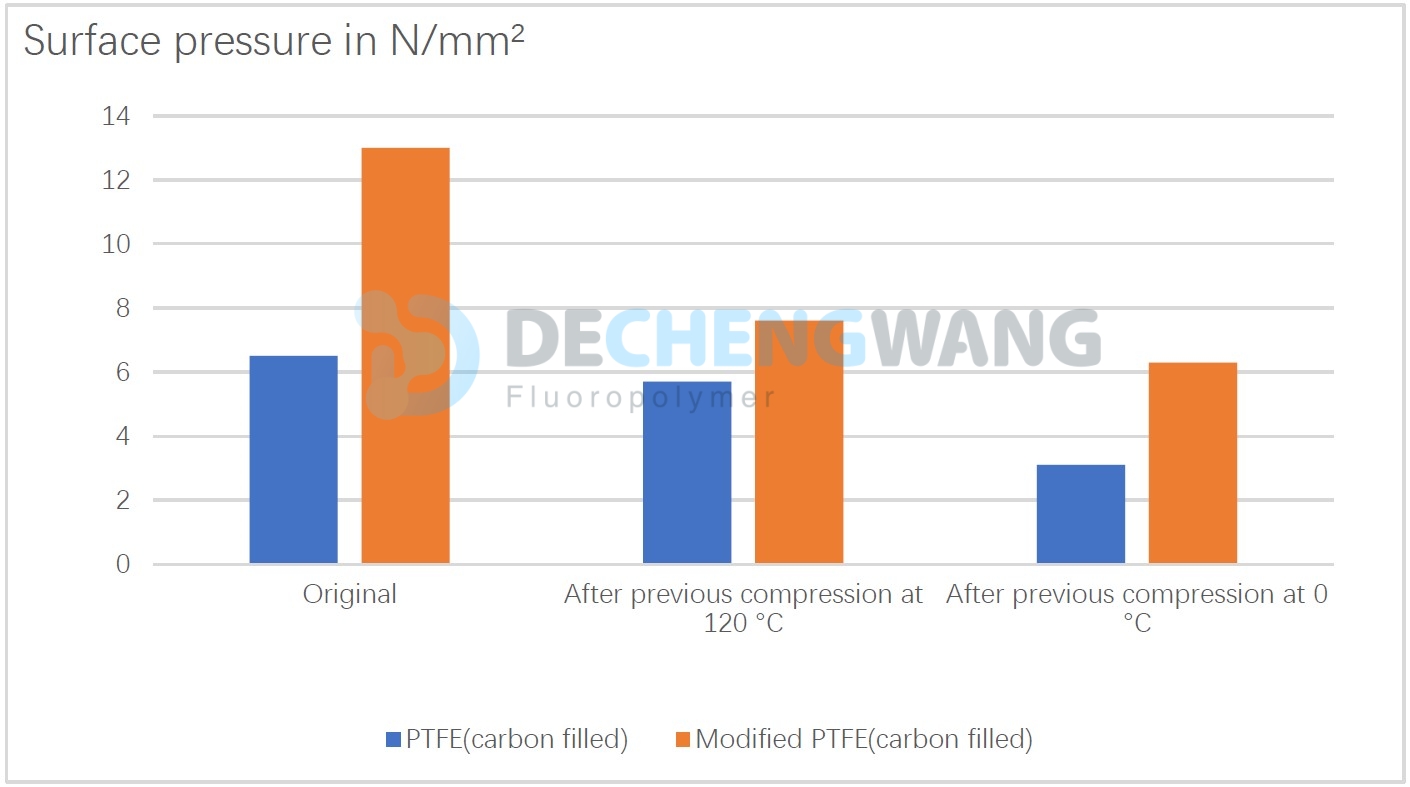

The cold flow or deformation under load of Modified PTFE is significantly lower than that of Standard PTFE. This applies both to unfilled Modified PTFE and Modified PTFE compounds.

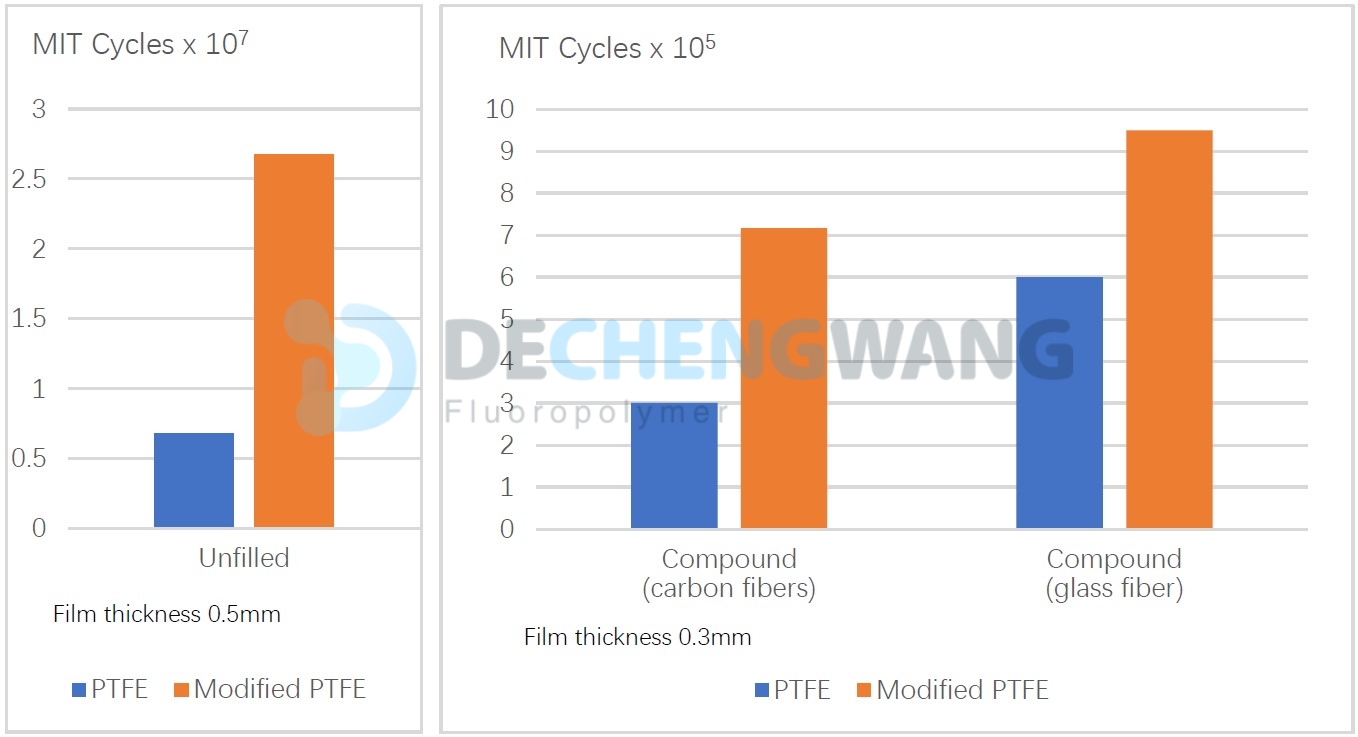

Flexural fatigue resistance

The modified PTFE has particularly good flexural fatigue resistance. Compared to standard PTFE, MIT tests show that modified PTFE has several times longer flexural life as that of standard PTFE. Even after the addition of inorganic fibers, the flexural fatigue resistance is better than that of standard PTFE. Because of this, modified PTFE can be used in dynamic applications which require a higher degree of reliability.

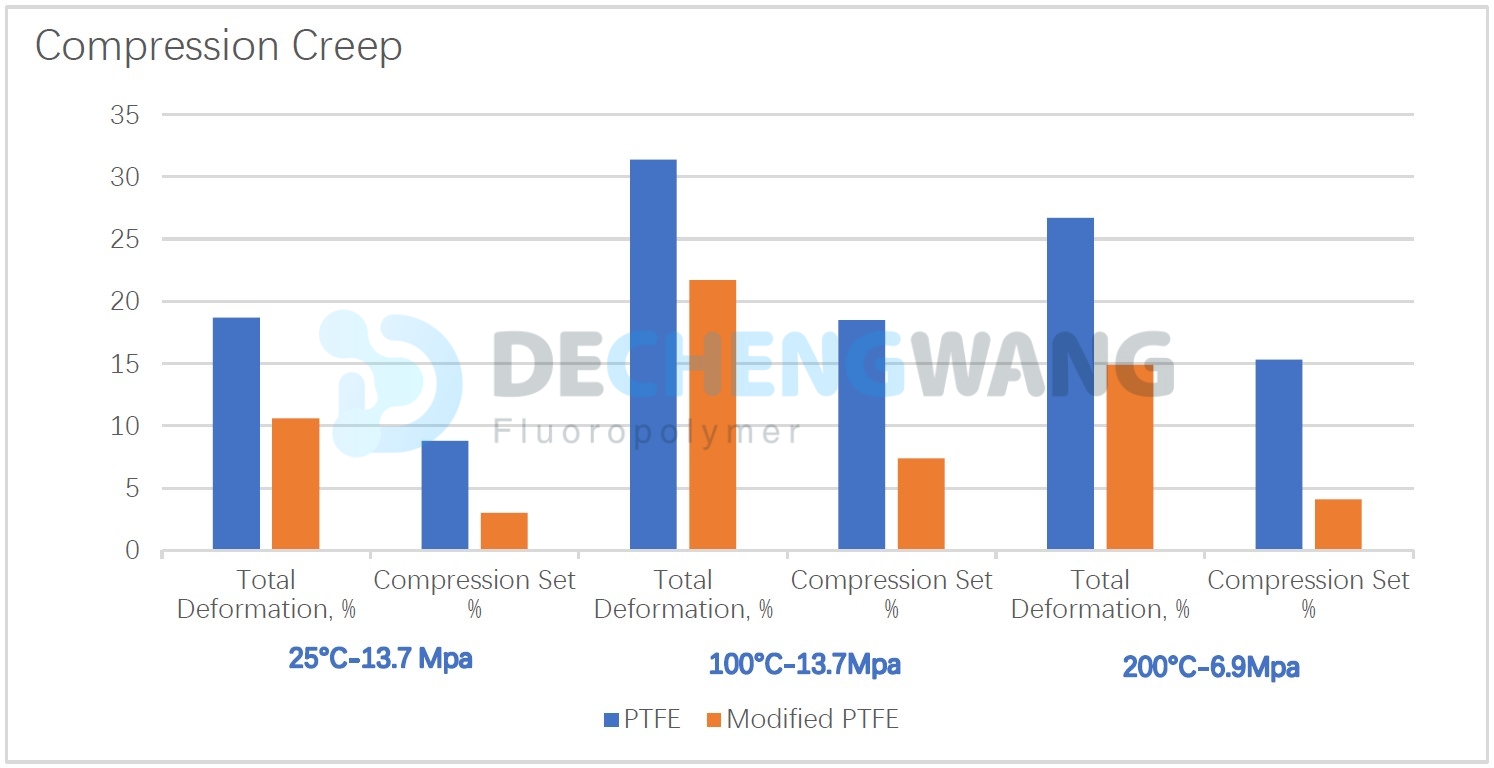

Reliability – especially at high temperatures.

Permanent total deformation after repeated loading of a test specimen, in each case measured at difference temperature.

For longer and smooth operation.

Stress recovery is important for applications such as seals, seats and gaskets where improved stress recovery can translate to longer sealability or less retorquing of parts. Modified PTFE exhibits better stress recovery than standard PTFE.

Regular Grades

Below are the popular grades of modified PTFE available on the market, each with its own unique set of properties and applications. At DECHENGWANG, we have a direct relationship with the PTFE resins and chemical suppliers, ensuring Full availability of all polymer resin available on the market. We are able to support your project with a reliable supply.

- TFM PTFE TFM-1600, TFM 1700 and TFM 1705 from Dyneon 3M,

- POLYFLON PTFE M111 and M112 from Daikin Industries, Ltd

- NXT-70, NXT-75 and NXT-85 from Chemours Company

- DF161 from Shandong Dongyue Polymer Material Co.,Ltd

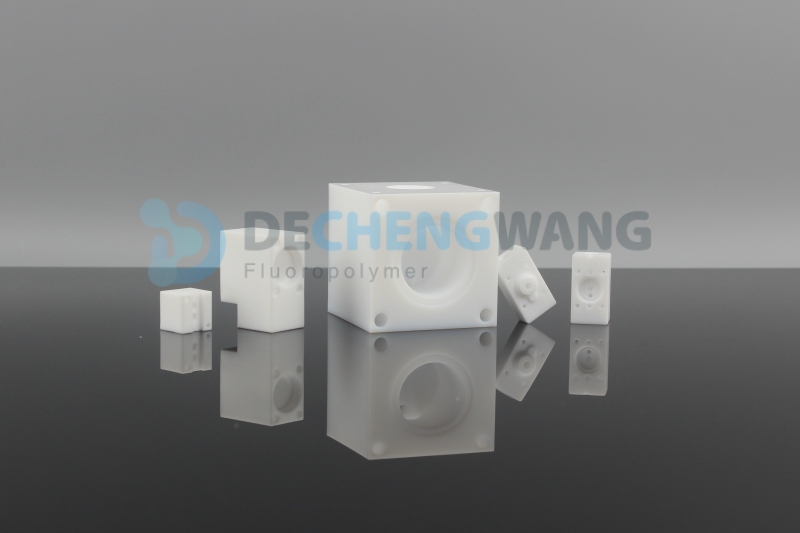

Applications

Modified PTFE is particularly suitable for use in applications where closed surfaces without pores are crucial. Products of modified PTFE with particularly smooth surfaces are of benefit when producing, transporting and storing ultra-pure chemicals, as well as in wet-chemical processes. The non-stick properties of modified PTFE make it resistant to adhesion by different substances, allowing for more efficient cleaning methods and shorter downtimes.

- Chemical processing engineering

- Fittings, shut-off devices, pumps, apparatus engineering

- Semiconductor industry

- Production, storage and transport of ultra-purity chemicals

- Electronics industry

- Machine and apparatus engineering

- Vehicle construction and aerospace industry

| Typical Application | Physical properties |

| PTFE Gaskets, PTFE seals | Creep resistance |

| PTFE Ball valve seats | Creep resistance |

| Automotive parts Power steering seals A/T seals Air conditioner seals Others | Creep resistance Flexural fatigue resistance Wear resistance |

| PTFE Bellows | Flexural fatigue resistance |

| Diaphragms | Flexural fatigue resistance |

| Metal inserts molded parts | Stress cracking resistance |

| Base powders (Compounds) | Creep resistance Flexural fatigue resistance |

Finding a Reliable Supplier

When looking for a reliable supplier of modified PTFE, it’s essential to consider several factors, including:

- Quality: Ensure your supplier obtains the raw material from right manufactures. At Dechengwang, we maintain a close relationship with PTFE resin and chemical suppliers, ensuring complete access to the entire range of polymer resins offered in the market.

- Experience: Choose a supplier that has experience in producing and supplying modified PTFE for your specific industry or application. DECHENGWANG has been in fluoropolymer filed for over 17 years. We have the Superior know how and high production potential to all grade of PTFE material.

- Cost saving: Dechengwang offers fully integrated Production chain of PTFE including Internal PTFE Post-treatment and Compounding ability, PTFE semi-finish processing(molding), makes us can Flexibility match customer’s technical request and cost reduction.

- Certifications: Choose a supplier that is certified to meet industry standards. As a testament to our commitment, all Dechengwang design, development, production and service facilities have achieved global ISO 9001 quality management certification, additionally, we achieve IATF 16949 quality management certification for our automotive clients.

In conclusion, the enhanced properties of modified PTFE make it ideal for applications beyond those of standard PTFE. When looking for a reliable supplier of modified PTFE, it’s essential to consider factors such as quality, experience, capabilities, and certifications to ensure that you get the best possible product for your needs.

For further technical information or demand, please feel free to contact us at info@ptfedf.com.