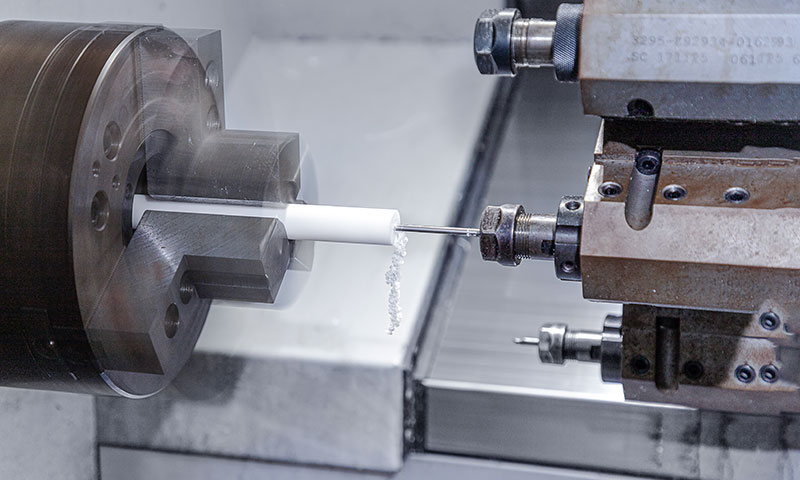

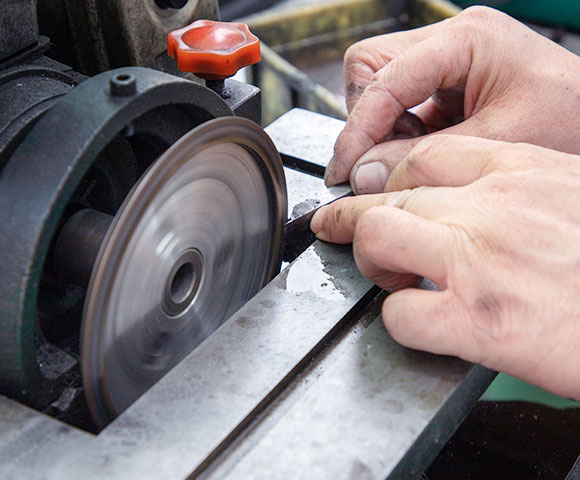

Dechengwang in-house tool & die design is critical to our success. Our engineers are experts at tool & die design, and we utilize state-of-the-art CAD/CAM software for our die designing process and produce dies and associated tooling with the close-tolerance precision our customers demand.

We will work with you to create tooling that matches the exact specifications and volume requirements of your part.