ISO/IATF Quality Assurance Approaches

A lasting quality assurance program to ensure that everything, from PTFE powder to finished parts are of the highest quality. See the stages our inspection process goes through.

A lasting quality assurance program to ensure that everything, from PTFE powder to finished parts are of the highest quality. See the stages our inspection process goes through.

We obtain all raw materials from selected suppliers known for their excellent quality. All materials and compounds are subjected to extensive analyses in our laboratory before being stored or processed. Our employees test, for example: Appearance Check/ Tensile strength/Dimension check/Density/Shore hardness/The composition of the compound

Appearance Check

- 01 -

Tensile strength test

- 02 -

Dimension Measuring

- 03 -

Density test

- 04 -

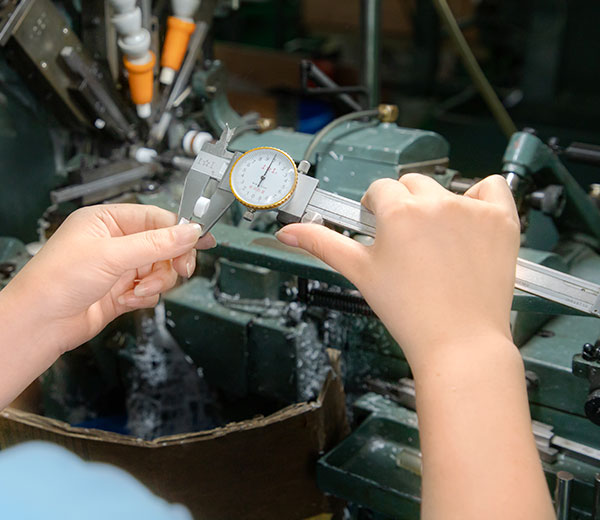

At every of our manufacture order, the First article inspection is required when machine set up, FAI will be done and record by IPQC and senior engineer. At every stage of production, the operator and IPQC inspection mainly focuses on critical dimension check.

Operators are in charge of machining inspection, especially for the critical size, first and end product of each material.

Material type, Job order, dimension, working instruction is within the manufacture order’s requirement.

First Article Inspection is to provide objective evidence that all engineering design and specification requirements are properly understood.

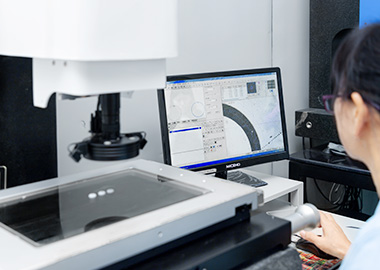

A pre-shipment inspection can ensure that your parts are produced as per requirement, before they are dispatched.

Dimension check by Profile Projector

Dimension check by go and no-go Guages

Physical inspection of packaging, labels and protection.

All process and inspection machines we equipped were designed for Fluoropolymer Parts. They help to assess the growth of PTFE products in a dynamic cycle of modernization.

Our professional PTFE molding and PTFE machining are always the reliable support that your PTFE project can count on.