When it comes to plastics, UV resistance or protection is an important factor to consider. Exposure to sunlight can cause plastics to degrade, leading to discoloration, brittleness, and ultimately, failure.

Fortunately, there are now several types of plastics available that are specially formulated to resist UV damage.

In this article, we will answer the question, “what is uv protection” and we’ll also take a closer look at 7 of the best uv resistant plastics on the market.

Basic Knowledge of UV Resistant Materials

UV-resistant materials are designed to resist fading, cracking, and other forms of damage caused by prolonged exposure to sunlight. They are commonly used in a variety of applications, including outdoor furniture, automotive parts, and building materials.

How Does UV Affect Plastics?

When exposed to UV light, plastic can undergo a process called photodegradation, which causes the material to break down and become brittle. This can lead to a shorter lifespan for plastic products.

UV radiation can also cause discoloration in plastic products, particularly those that are light-colored or transparent. This is because UV light can break down the pigments and dyes used in the plastic, resulting in a yellowing or browning effect.

This not only affects the appearance of the product but can also impact its functionality and durability.

Why is UV-Resistant Material Important?

The uv resistant materials are important for preserving the quality and longevity of products. Without UV protection, materials such as plastics, fabrics, and paints can fade, crack, or become brittle over time. This can result in a shorter lifespan for products, leading to more waste and increased costs for replacements.

In addition to that, UV-resistant material is essential for outdoor applications. Outdoor furniture and other structures are constantly exposed to the sun’s rays. UV-resistant materials can withstand this exposure and maintain their appearance and functionality for longer periods.

What Makes a Plastic Material UV Resistant?

Plastic materials can be made UV resistant through the addition of certain chemicals such as UV stabilizers and black coloration. These chemicals absorb UV radiation and convert it into heat, preventing it from damaging the plastic.

One common UV stabilizer is benzophenone, which is often used in polyethylene and polypropylene plastics. Another common stabilizer is hindered amine light stabilizers (HALS), which are used in a variety of plastic materials.

By carefully selecting the right combination of additives and properties, UV-resistant plastic manufacturers can create plastics that can withstand exposure to UV radiation and maintain their strength and durability over time.

7 High-performance UV Resistant Plastics

High-performance uv resistant plastics are a popular choice for various applications due to their exceptional properties. Here are seven of the best options available in the market today; PTFE, PVDF, HDPE, PEI, PPS, Acrylic, and Polycarbonate.

PTFE

PTFE, or polytetrafluoroethylene, is known for its exceptional uv resistance of plastics. It is made from carbon and fluorine atoms. PTFE is commonly used in outdoor applications such as electrical insulation, cable jacketing, and solar panel components.

Unlike other plastic uv resistance that can become brittle and crack when exposed to UV radiation, PTFE remains flexible and durable. This makes it an excellent choice for applications that require long-term reliability and performance.

In addition to its UV resistance, PTFE is also known for its chemical resistance, low friction, and high-temperature tolerance.

These properties make it a versatile material that is used in a wide range of industries, including aerospace, automotive, and medical.

Related Blog: >> What is PTFE

PVDF

PVDF is highly resistant to chemicals, and abrasion, making it a durable and reliable choice for a wide range of applications. This makes it a popular choice for applications that require a high level of durability, such as piping systems, tanks, and valves.

Another key benefit of PVDF is its ability to maintain its mechanical properties even after prolonged exposure to UV radiation. That is why it’s also an ideal choice for outdoor applications such as building facades, and roofing.

HDPE

HDPE, or high-density polyethylene, is a type of plastic that is known for its high-performance capabilities. It is from the ethylene family.

One of its most notable features is its ability to resist UV radiation, making it a popular choice for products such as outdoor furniture, playground equipment, and even marine structures.

In addition to its UV resistance, this material is also resistant to chemicals, making it a popular choice for industrial applications. Its versatility and strength make it a reliable choice for a wide range of applications.

PEI

PEI, or Polyetherimide, is also known for its exceptional uv resistance of plastics. In addition to its durability, PEI is also a lightweight material. This makes it a great option for industries where weight is a concern, such as the manufacturing of electronic components.

Its ability to maintain its strength and shape under stress also makes it a popular choice for structural applications. PEI is a versatile material that offers a range of benefits for various industries.

PPS

PPS, or polyphenylene sulfide, is a high-performance engineering plastic with a variety of advantages for a variety of uses. One of its most notable benefits is its resistance to UV radiation, which makes it a popular choice for outdoor goods and devices.

UV resistance can improve the longevity and durability of goods that are exposed to sunlight. PPS has proven to be a dependable and effective UV protection material in everything from automotive parts to electrical components.

Acrylic

Acrylic is a type of plastic that’s great for outdoor use because it’s resistant to UV radiation from the sun. Acrylic has a high percentage of a chemical called MMA, which absorbs UV radiation.

Plus, it can be mixed with other substances to make it even more resistant to UV. Acrylic is also clear, which means it lets light through while still being UV resistant. That’s why it’s often used in things like signs, windows, and skylights.

Polycarbonate

According to a study published in the journal Polymer Degradation and Stability, polycarbonate exhibits excellent resistance to UV radiation due to its chemical structure, which contains benzene rings that absorb UV light. The study also found that adding UV stabilizers to polycarbonate further enhances its UV resistance.

Therefore, polycarbonate is commonly used in applications where UV resistance is critical, such as in outdoor signage, protective eyewear, and greenhouse panels.

Applications of UV Protective Plastic

The applications of uv protective plastic can provide an effective barrier against harmful UV radiation. These applications can be used in a variety of settings, including outdoor furniture, automotive parts, and even medical equipment.

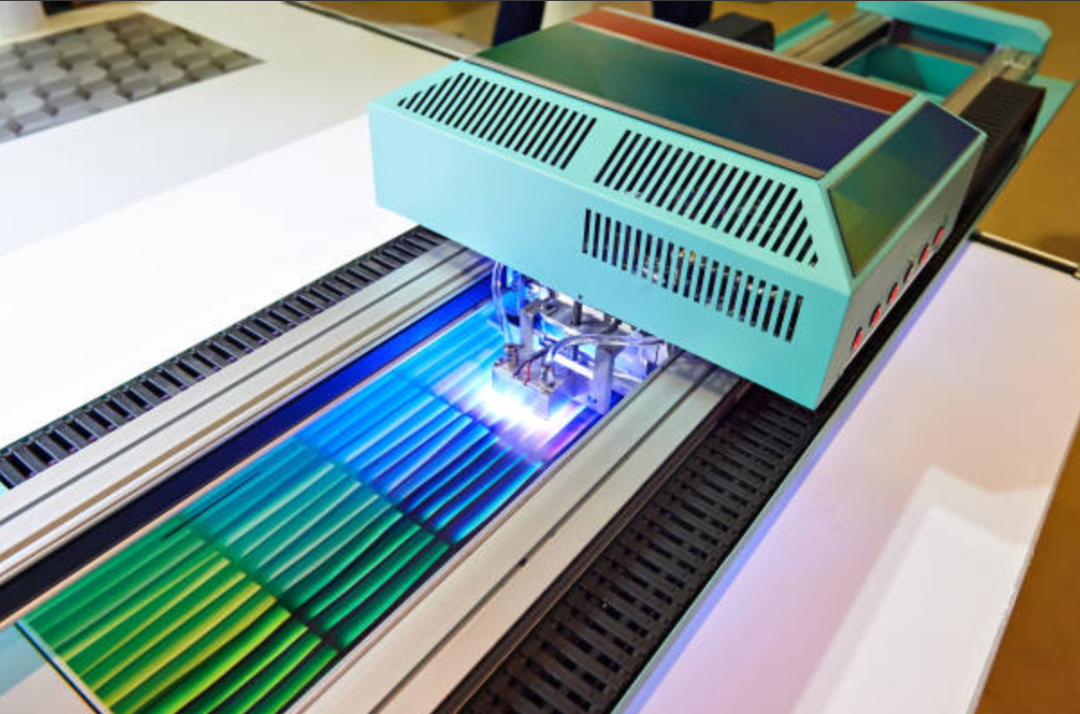

Solar Energy Infrastructure

Solar energy infrastructure has been revolutionized by the application of UV-protective plastic.

This plastic is designed to protect solar panels from the harmful effects of UV radiation, which can cause damage and reduce their efficiency over time.

With the use of UV-protective plastic, solar panels can last longer and require less maintenance, making them a more cost-effective and sustainable option for energy production.

Farm Machinery

The benefits of using UV-protective plastic on farm machinery are numerous. Not only does it help protect crops from UV radiation, but it can also help extend the life of the machinery itself.

By using uv protection plastic, farmers can help prolong the life of their machinery and save money on repairs and replacements.

Outdoor Scientific Instruments

UV-resistant plastic contains additives that block or absorb UV radiation, preventing it from reaching the plastic’s surface and causing damage. It is also more durable and weather-resistant than regular plastic, making it suitable for outdoor use.

Examples of outdoor scientific instruments that commonly use UV-resistant plastic include weather stations, air quality monitors, and water quality sensors. These instruments are often exposed to sunlight and other environmental factors, making UV-resistant plastic crucial for their performance and longevity.

Building Materials

UV protective plastic is a versatile building material. This plastic is designed to protect against the harmful effects of ultraviolet radiation, which can cause damage to building materials over time.

UV protective plastic offers a range of benefits. From roofing and siding to windows, this material can help to protect buildings from the harmful effects of UV radiation while also improving energy efficiency and extending the life of the building.

Vehicle Decoration

UV-resistant plastic is commonly used in vehicle decoration to protect against fading and cracking caused by exposure to sunlight. Examples include exterior trim pieces, such as side mirrors, door handles, and grille accents, as well as interior components, such as dashboards, door panels, and seatbacks.

By using UV-resistant plastic, vehicle manufacturers can ensure that the vehicle looks new and maintains its aesthetic appeal over time.

DCW: Your One-Stop Supplier of UV Protected Plastics

If you are looking for a reliable uv protected plastic supplier for any high-performance UV-resistant plastic, DCW is your one-stop supplier for uv protective plastics.

DCW is dependable for the supply of uv protection plastics for solar energy infrastructure, farm machinery, outdoor scientific instruments, building materials, vehicle decoration, etc. Their products are designed to be reliable, efficient, and long-lasting ensuring that customers are satisfied.

DCW makes use of different materials for the production of UV-protective plastics to suit the taste of its customers. UV protective plastics are available in whatever kind of material you need them.

Their team of experts is always on the desk to answer any questions or concerns that customers may have, and they are committed to providing the best possible experience for their customers.

Conclusion

This article has given you a detailed introduction to 7 UV-resistant plastics and how to identify the types of plastic that are UV-resistant materials through their characteristics.

By carefully looking at the harmful effect of UV radiation and the damages it will cause, people will begin to see the need for UV protective plastics and the more the need for UV protective plastics will arise.

With the service of DCW, you can be sure to get high-quality UV protective plastics.