Teflon is one of the most widely used, multipurpose products in the world. This synthetic polymer has become synonymous with chemical and heat-resistant materials, which is why it’s found in an array of applications ranging from industrial and electrical to domestic uses.

Its temperature resistance makes it suitable for use in high-temperature environments. There are many uses of teflon, and it is applied in different applications in a wide range of industries. This blog aims to provide an introduction to Teflon, its history and development, why it is such a widely used material, what makes it so unique, and how it can be used.

What Is Teflon

Teflon, also defined as polytetrafluoroethylene (PTFE), is a versatile synthetic material discovered by a chemist named Roy Plunkett in 1938. Because of its unique properties, there have been many uses of teflon in a wide range of industries and applications since then.

It has a low coefficient of friction and is highly resistant to corrosion, heat, and chemicals. Due to its unique qualities, it has been used to coat cookware, machinery, and piping systems. Its non-stick properties make it ideal for use in household items such as frying pans and baking sheets.

Teflon’s diversity is further evident in its various forms. It can be found as a solid material, a powder, or a liquid, depending on its intended use. Its versatility has made it a popular choice in a variety of industries, including automotive, aerospace, electronics, and more.

The Properties and Advantages of Teflon

Teflon has several unique properties that give it significant advantages over other materials. Teflon’s unique properties make it an ideal material for use in a variety of industries.

Its chemical resistance, weatherability, insulating properties, non-flammability, flexibility, non-stickiness, slippery surface, and broad working temperature range give it significant advantages over other materials. Teflon is a unique material with several characteristics that make it stand out from other materials. Here are some of its distinctive features.

Chemical Resistance

This is one of Teflon’s most prominent properties, making it highly resistant to acids, bases, and most organic solvents. This property makes it ideal for use in harsh chemical environments, such as in the chemical and pharmaceutical industries. What is teflon used for is to construct reaction vessels, piping, and tubing, where it can withstand exposure to corrosive chemicals without degrading or losing its properties.

Weatherability

The weatherability of teflon is one of its best characteristics, as it offers superior protection against the elements. Teflon is a synthetic polymer of fluoropolymer resin which provides superior flexibility and an extremely low coefficient of friction. It is highly resistant to abrasion and UV light, making it ideal for many weatherproof applications, such as protecting exterior components from rain, snow, dirt, and other environmental conditions.

Teflon is a material that is extremely resistant to the elements. It is able to stay intact when exposed to ultraviolet light and extreme temperatures. Examples of materials that can benefit from using teflon include electrical insulators, wire and cable coatings, and other materials that are exposed to the elements. Its ability to remain effective despite extreme temperatures and UV light make it an ideal candidate for outdoor products.

Insulativity

Another advantage of Teflon is its high dielectric strength, which makes it an excellent insulating material for use in electrical applications. The use of teflon coating in wires and cables in high-voltage applications because it can withstand high voltages without breaking down or losing its insulating properties.

The primary reason why teflon has such high insulativity is its molecular structure. The molecules of teflon are arranged in such a way that they resist the flow of heat energy. This means that when heat is applied to the material, the molecules vibrate and absorb the energy, preventing it from moving in any direction. As a result, teflon can stay hot or cold for longer than many other materials.

Non-flammability

Teflon is also highly non-flammable, which makes it ideal for use in fire suppression systems and as a coating on fabrics to make them flame-resistant. When teflon burns, it does not emit toxic fumes, making it a safer choice than other materials.

This is one of its most important characteristics, as it makes it ideal for applications where fire safety is a major concern. Teflon’s non-flammability comes from the fact that it does not ignite when exposed to open flames or heat. The polymer’s chemical structure prevents combustion and makes it resistant to high temperatures.

Flexibility

Teflon is renowned for its flexibility and durability. It is a material that can adapt to a variety of conditions and is resistant to wear and tear, making it an excellent choice for a wide range of applications in industry and everyday life.

Teflon is flexible as it can be molded into complex shapes and used in applications where flexibility is critical, such as gaskets, seals, and other parts that require flexibility. Another uses of teflon as a coating on fabrics prove that they are flexible and durable.

Non-Stickiness

One of teflon’s most well-known properties is its non-stickiness. Teflon has a low coefficient of friction, which means that it is highly resistant to sticking. The non-stickiness of teflon comes from its low surface energy; this means that it does not cling to other materials, making it ideal for cookware, textiles, and other products that must be easy to clean.

This property makes it an excellent material for use in non-stick cookware and bakeware, as well as in the food packaging industry. The use of teflon coating on cutting tools to reduce friction and increase their lifespan.

Slippery Surface

Its slippery surface is another desirable property that makes it useful in many applications of PTFE. Its low coefficient of friction makes it an ideal material for use in bearings, bushings, and other sliding components. Teflon is also used as a coating on conveyor belts, slides, and other materials to reduce friction and wear.

Broad Working Temperature Range

Finally, teflon has a broad working temperature range, making it suitable for use in high-temperature applications such as aerospace, automotive, and industrial applications. Teflon can withstand temperatures ranging from -200°C to 260°C without degrading or losing its properties.

Teflon’s extensive temperature range can be attributed to a number of its inherent characteristics. Its high-molecular weight makes it highly resistant to chemical attack, while its low coefficient of friction reduces wear and guard against temperature increases due to friction-generated heat.

10 Popular Industrial Applications of Teflon

Teflon is a versatile synthetic material that has found widespread use in many industries. Its unique properties, including chemical resistance, non-stickiness, and high-temperature resistance, make it an ideal material for a variety of industrial applications. From aerospace to food processing.

Teflon has become an essential material in modern industry, revolutionizing the way products are manufactured and used. Here are some of the most popular industrial applications of PTFE and how it has transformed various industries.

Applications of Teflon in Chemical Field

Teflon’s chemical resistance and non-stickiness make it an ideal material for use in the chemical industry. It is commonly used to manufacture chemical processing equipment such as reactors, distillation columns, and storage tanks. Teflon is highly resistant to acids, bases, and most organic solvents, making it an ideal material for handling corrosive and reactive chemicals.

Its non-stickiness also ensures that the chemicals do not adhere to the surfaces, reducing the risk of contamination and improving the efficiency of the processes. In addition to manufacturing chemical processing equipment, teflon is used for making laboratory equipment such as beakers, flasks, and pipettes. Its chemical resistance and non-stickiness make it an ideal material for handling and storing chemical samples without contaminating them.

Teflon is also used to coat stirring bars and other laboratory tools to prevent sticking and facilitate the mixing of chemicals. Teflon’s unique properties have revolutionized the chemical industry by improving the safety and efficiency of chemical processing and analysis.

Uses of Teflon in Aerospace Industry

One of the applications of PTFE is the aerospace industry because it requires materials that can withstand harsh conditions, extreme temperatures, and high stress. Teflon’s unique properties make it an ideal material for many aerospace applications. For example, Teflon is used in the aerospace industry to coat bearings, bushings, and other components that require a low coefficient of friction. Teflon’s low friction properties help reduce wear and tear on components and improve their lifespan.

Teflon is also used in aerospace as a high-temperature insulation material. It has excellent insulating properties, which make it ideal for use in thermal protection systems that protect spacecraft from the heat generated during reentry. Additionally, Teflon is used to coat wires and cables in aerospace applications where high reliability and durability are essential.

Moreover, teflon is used in the manufacturing of critical components such as fuel hoses and gaskets in aerospace vehicles. Teflon’s resistance to chemicals, heat, and pressure makes it an ideal material for these applications.

Uses of PTFE in Automotive Industry

Teflon has numerous applications in the automotive industry. One of the primary uses of teflon in vehicles is in coating various engine components to reduce friction and wear. This helps to improve the engine’s performance, efficiency, and lifespan.

What is teflon used for in the automotive industry are also for coating brake pads, which helps to reduce brake dust and noise. Teflon-coated brake pads also have improved heat resistance and reduced wear, resulting in longer-lasting and more effective braking.

Another application of teflon in the automotive industry is in the manufacturing of fuel lines and hoses. In addition, Teflon is used in the production of automotive gaskets and seals. Teflon’s ability to resist high temperatures and chemical degradation makes it an ideal material for these critical components.

Overall, Teflon’s unique properties make it an indispensable material in the automotive industry, helping to improve performance, reduce wear, and increase the lifespan of various components.

Applications of PTFE in Mechanical Engineering

Teflon is widely used in mechanical engineering due to its unique combination of properties. One of the primary application of teflon is in coating various mechanical parts to reduce friction and wear. This helps to increase the durability and efficiency of machines and equipment, leading to longer lifespans and lower maintenance costs.

Another use of PTFE in mechanical engineering is when making bearings, gears, and other components that require high strength, low friction, and chemical resistance. Teflon is also used in the production of seals, gaskets, and packing materials due to its excellent chemical resistance, which makes it ideal for use in harsh environments.

Teflon is also used in the production of conveyor belts and other materials handling equipment, as it can withstand high temperatures, harsh chemicals, and extreme conditions.

Overall, Teflon’s unique properties make it a valuable material in mechanical engineering, helping to improve performance, reduce wear, and increase the lifespan of various components and equipment.

Uses of Teflon in Electronics and Semiconductors

Teflon has a range of unique properties that make it an ideal material for use in electronics and semiconductors. One of the key advantages of Teflon is its high resistance to heat, chemicals, and electricity. This makes it useful in a variety of applications where insulation is required.

One important application of teflon in electronics is as a dielectric material for capacitors and printed circuit boards (PCBs). Teflon’s high dielectric constant, low dissipation factor, and high thermal stability make it an ideal choice for these applications. Additionally, Teflon’s non-stick properties make it useful in the fabrication of electronic components such as wafer carriers, which prevent silicon wafers from sticking to processing equipment during manufacturing.

Teflon is also used as a coating for wires and cables in high-temperature applications, where its high resistance to heat and chemicals protects against damage and corrosion.

Application of Teflon in Oil and Gas Industry

Teflon is an incredibly versatile material and it has been designed in a variety of applications in the oil and gas industry. One of its most common uses is as a sealant, due to its low friction and non-stick properties. It is popular for sealing pipe threads, gaskets, and valves since it prevents leakage of oil and gas from the pipes. Another application is as a coating for downhole tools, such as drill bits and tubing.

The Teflon helps reduce wear and tear on these parts, extending the lifespan of the tools. Additionally, Teflon is also used for protecting sensitive electronic components from corrosion. In this application, it is often applied as a protective plastic film or coating. As consumers can see, Teflon provides numerous benefits to the oil and gas industry and has become an invaluable material in modern engineering.

Uses of PTFE in Medical Sector

Teflon has several applications in the medical sector owing to its physical and chemical properties. It is a non-reactive material with high heat resistance and low surface tension, making it ideal for medical applications such as implants, tubes, catheters, and other medical equipment. Teflon is used for making implants that are resistant to infection, due to the fact that bacteria and other microorganisms cannot adhere to the surface.

It is also used in antiperspirant patches and wound dressings, as it has excellent water-repellent qualities while remaining breathable. Furthermore, Teflon is highly flame retardant, making it a preferred material for certain types of surgical masks.

Lastly, Teflon is used in sutures due to its durability against frictional wear, abrasion, and corrosion. All of these characteristics make teflon an excellent material for a variety of medical applications.

Applications of PTFE in Food and Beverage Industry

Teflon is a common material used in many aspects of the food and beverage industry. It is often applied in the production of cooking pans, as it provides a durable, non-stick surface that is easy to clean and highly heat resistant. Teflon is also used to coat the interior of food and beverage containers, as it helps protect against corrosion and contamination caused by acidic ingredients or oxidizing agents.

In addition, due to its chemical inertness, it can be used to create seals for beverage containers that prevent leaking or evaporation during storage. Another uses of PTFE is to coat the surfaces of beverage processing and bottling equipment, where it helps prevent the buildup of deposits that can reduce efficiency. Overall, Teflon’s strong chemical resistance and high-temperature tolerance make it an ideal material for use in the food and beverage industry.

Use of Teflon Coating in Cooking Utensils Making

Teflon is a synthetic polymer best known for its non-stick properties. It is commonly used to coat cooking utensils, surfaces, and other cookware. Teflon provides a number of advantages in the kitchen, such as reducing cleanup time and preventing food from sticking to surfaces during cooking.

Additionally, the very low surface energy of teflon helps repel water and oil-based liquids, making it ideal for protecting kitchen surfaces from liquids and minimizing their spread.

By the use of teflon coating, it enables food to cook faster and more evenly. The heat is transferred more quickly throughout the pan, helping to prevent undercooked or burned areas.

Teflon’s superior heat resistance also makes it suitable for use with higher temperatures than many other types of cookware. Because of its numerous advantages, Teflon has become an indispensable tool in the kitchen for those who want to make meal preparation easier and safer.

Uses of Teflon in Making Personal Care Products

Teflon has properties that have made it ideal for applications in personal care products such as cosmetics, hair care, and skincare products. Its non-stick surface makes what is teflon used for for dusting powders, which are used to absorb oil and sweat from the skin..

Its non-reactive surface also prevents damage to delicate facial tissues like eyes and lips. In addition, its hydrophobic nature keeps makeup products from running or smudging when applied to the skin. The same property also makes it suitable for waterproof mascara and setting sprays.

Moreover, Teflon is perfect for formulating sunscreens and other skin protectants because it helps reduce the penetration of UV rays into the skin. Finally, its thermal stability allows for the use of hot tools like blow dryers safely on the hair. All in all, these are one of the many application of teflon in personal care products, making it a valuable ingredient in product formulations of this industry.

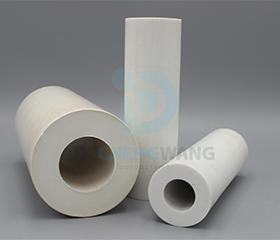

A Trustworthy Teflon Molding & Machining Services Provider: DECHENGWANG

DECHENGWANG is a highly trusted and experienced teflon molding and machining services provider, specializing in the production of high-quality teflon products for a wide range of industries. With years of experience and expertise, DECHENGWANG offers an array of teflon molding and machining services, including customized materials, sizes, and machining, to meet any applications of PTFE to its clients.

One of the key services offered by DECHENGWANG is the customization of teflon materials to meet specific client needs. They offer a wide range of materials, including PTFE, PEEK, PFA, PCTFE, and PVDF, all of which can be customized to meet specific requirements. Whether clients require unique chemical or temperature resistance, electrical properties, or other specific characteristics, DECHENGWANG can provide customized teflon materials to meet their needs.

In addition to customized materials, DECHENGWANG also offers customized sizes for teflon products, depending on the uses of PTFE. Their experienced team can create products of any size, from small components to large-scale machinery parts. This ensures that clients get the exact product they need, no matter how large or small.

They also offer machining services for the different uses of teflon products. They utilize the latest machining technology and equipment to produce high-quality products with tight tolerances and precise dimensions. Their machining services include Premium PTFE Compression Molding, automatic production, CNC Lathe machining, CNC machining, and stamping, ensuring that clients receive products that meet their exact specifications.

At DECHENGWANG, they take pride in providing its clients with the highest quality teflon products possible. Their products are designed and manufactured according to stringent industry standards, and they strive to ensure that each product meets the expectations of its customers.

Conclusion

Teflon is an incredibly versatile material that is used in an array of industrial applications due to its unique properties. Some of the most popular industrial applications include the use of teflon coating for non-stick surfaces, insulation for electrical components, and sealing materials for high-pressure systems.

If a consumer is looking for a reliable and experienced teflon molding and machining services provider, DECHENGWANG is an excellent choice. They offer customized materials, sizes, and machining services to meet the particular needs and requirements of their clients. With years of experience and expertise, DECHENGWANG can provide high-quality teflon products that meet even the most demanding specifications.

Get in touch with them today to get a quote. Their team of experts will work closely with consumers and different industries to understand their needs and develop customized solutions that meet their specific requirements. Contact DECHENGWANG today and experience the benefits of high-quality Teflon products for any industrial applications.