When it comes to choosing a PTFE supplier for your PTFE (commonly known as Teflon) project, it is essential to consider several factors to ensure you find a reliable and capable supplier. PTFE is a versatile material with numerous applications in industries such as automotive, medical, aerospace, electronics, chemical, manufacturing and more. In this blog post, we will discuss the top five factors to consider when selecting a PTFE supplier, including direct relations with PTFE resins and chemical suppliers, internal PTFE compounding capabilities, expertise in producing PTFE finished parts, availability of technical support, and a commitment to quality guarantee.

Factor 1, Direct Relation with PTFE Resins and Chemical Suppliers:

A reputable PTFE supplier should have a direct relationship with trusted PTFE resins and chemical suppliers. This ensures that they source their raw materials from reliable sources, resulting in consistent performance and reliability in the PTFE products they offer. A direct relationship with suppliers also enables better communication, faster lead times, and access to the latest advancements in PTFE materials. DCW is fully familiar with the PTFE grade on the market, which can easy match customer’s requirement.

Below are some regular brand of PTFE (Granular PTFE) on the market, including standard PTFE and modified PTFE:

Teflon® PTFE from Chemours

- Teflon® PTFE 7A X

- Teflon® PTFE 7C X

- Teflon® PTFE 8A X

- Teflon® PTFE 807N X

- Teflon® NXT 70 Modified PTFE

- Teflon® NXT 75 Modified PTFE

- Teflon® NXT 85 Modified PTFE

POLYFLON™ PTFE from Daikin

- POLYFLON™ M-12 PTFE

- POLYFLON™ M-17 PTFE

- POLYFLON™ M-18 PTFE

- POLYFLON™ M-18F PTFE

- POLYFLON™ M-111 Modified PTFE

- POLYFLON™ M-112 Modified PTFE

Dyneon™ PTFE from 3M™

- Dyneon™ PTFE TF 1620

- Dyneon™ PTFE TF 1645

- Dyneon™ PTFE TF 1750

- Dyneon™ TFM™ 1600 Modified PTFE

- Dyneon™ TFM™ 1700 Modified PTFE

- Dyneon™ TFM™ 1705 Modified PTFE

Algoflon® PTFE from Solvay

- Algoflon® F 5/S PTFE

- Algoflon® F 5 PTFE

- Algoflon® F 7 PTFE

- Algoflon® F S 121 PTFE

Fluon® PTFE from AGC Chemicals

- Fluon® G110 PTFE

- Fluon® G155 PTFE

- Fluon® G163 PTFE

- Fluon® G204 PTFE

Factor 2, Internal PTFE Compounding and PTFE Semi-Finish Processing (Molding):

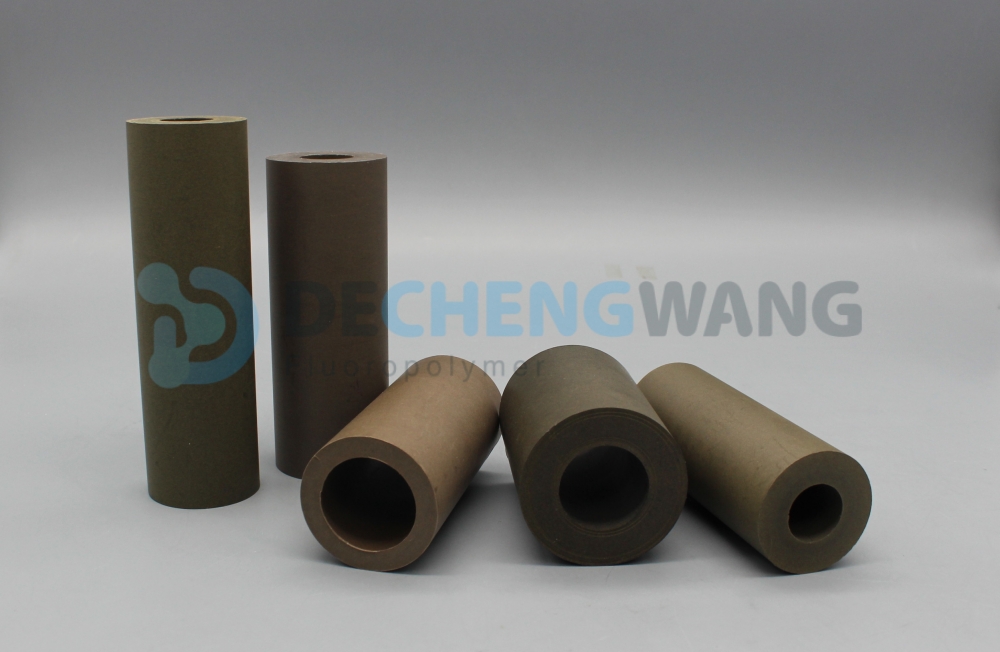

Consider choosing a supplier that has expertise in internal PTFE processes, such as sintering, compression molding and PTFE material compounding. These processes enhance the properties of PTFE and tailor it to specific applications. Additionally, to have the ability of in-house PTFE semi-finished processing, such as PTFE rod, PTFE tube and PTFE sheet, opt for a supplier who can provide these services in-house. This ensures better quality control, shorter lead times, and the ability to customize products according to your specifications. Moreover, production chain fully integrated can also reduce the cost.

Here are some examples of our PTFE compounding, we also can provide according to your requirement.

- Glass filled PTFE

- Carbon filled PTFE

- Carbon fiber filled PTFE

- Graphite filled PTFE

- Bronze filled PTFE

- PEEK filed PTFE

- Pigment filled PTFE

- And many more organic and inorganic fillers.

Base PTFE can choose from standard PTFE or modified PTFE, combinations of 2 or 3 filler is available.

Factor 3, Finished Parts: Superior Know-how, High Production Potential:

If you need finished PTFE parts or components, it is crucial to select a supplier with superior know-how and a high production potential in this area. PTFE machining requires specialized skills and knowledge due to it has a much higher coefficient of thermal expansion than metals and therefore heat accumulates rapidly during processing affecting the range of tolerances that can be guaranteed on machined components. Internal tensions in the semi-finished material will also influence the processing and the actual final dimensions.

Look for a supplier that has extensive experience and expertise in manufacturing finished PTFE parts. Their knowledge of design, machining techniques, and production processes will ensure that you receive high-quality parts that meet your specific requirements, at the same time, they can provide the most cost efficiation process method for your project. Additionally, a supplier with a high production potential can accommodate larger orders and deliver on time.

At DCW, we produce lots Finished machined parts in virgin, modified, filled PTFE & high performance plastic materials with our CNC lathes & milling machines, such as:

- Ball Valve seats, Diaphragm, gaskets, seals

- rings; back-up rings; V rings; Chevron rings; Washers

- Spheres; Bellows; Lip seals, Piston Seals

- Wide range of customized parts on customer drawing

Factor 4, Technical Support of the PTFE supplier:

Today’s designers and engineers are faced with an overwhelming array of high performance plastic options and processing techniques. This vast selection necessitates making compromises with every choice.

At DCW, we comprehend the impact of processing on the standard characteristics of high performance plastics. Our expertise and technical know-how enable us to aid you in selecting a material that fulfills your needs and suits your operating environment.

Factor 5, Quality Guarantee of the PTFE supplier:

Finally, when choosing a PTFE supplier, always look for quality assurance measures. A reputable supplier should have robust quality control systems in place, DCW is running ISO 9001 and IATF 16949 quality management system from PTFE resin to finished parts at our plant. Our Quality Team always Committed on guarantee the best and most reliable control for our final products.

These certifications indicate that DCW adheres to international quality standards, follows stringent processes, and consistently delivers products that meet or exceed customer expectations. Working with a certified supplier not only ensures product quality but also instills confidence in their commitment to continuous improvement and customer satisfaction.

At DCW, we are equipped with in-house laboratories, constantly carrying out material testing focused on material quality assessment. Our R&D material lab can provide test not limited to the following:

- Tensile strength

- Hardness

- Specific gravity

- Dielectrical resistance

- Thermal Expansion

- Wear and Friction

- Roughness measurement

- Irradiance test

- Surface Profiler

- Dimension projector

- Dimensional inspection by HD camer

Conclusion:

Choosing the right PTFE supplier is crucial for ensuring the success of your projects and the performance of your products. By considering factors such as direct relations with PTFE resins and chemical suppliers, internal post-treatment capabilities, expertise in producing finished parts, availability of technical support, and a commitment to quality guarantee, you can make an informed decision. Take the time to evaluate different suppliers, request samples, and ask for references to ensure that you find a reliable and capable PTFE supplier that meets your specific needs.

Contact our experts to know more. info@ptfedf.com