Custom Performance & Design

In house material compound capability and rich experience in PTFE filed can full fill your PTFE Teflon bellow project.

PTFE bellows are used as balancing elements between engineering parts, which is widely used in chemical, food and medical appliances. The different geometres of the folds highly flexible or pressure-resistant versions can be designed and manufactured to reach higher flexibility or compressive strength. External and internal Pressure, number of runs and all -closed/ all-open lengths are the critical factors to consider in designing a bellow.

Whether your PTFE bellow requirements are simple or complex, our experts have the ability to customized Design and Performance. The outstanding material properties of modified PTFE and PTFE compound allow bellows to be used increasingly in the medical and food sectors, as well as in general industry in:

PTFE 14 Bellows 0901736838

PTFE 3 Bellows 8125500406

PTFE 8 Bellows 1322500620

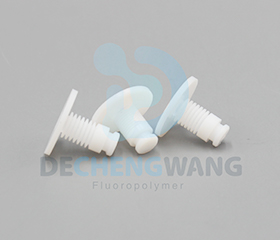

PTFE Bellow

PTFE Bellows with FKM o ring

PTFE Bellows

PTFE Compound Bellow

PTFE Micro Bellows

| Material Name | Main Properties | Notes | Temperature Range |

| PTFE | General Purpose ;

Unfilled PTFE with FDA-conformance |

FDA approved | -180°C to 260°C |

| Modified PTFE | Excellent Flexibility;

Excellent Creep Resistance; higher reverse bending strength |

FDA approved | -180°C to 260°C |

| PTFE compound | With an application as metering, shut-off and sealing element the clamping flange, the sealing cone or the slide ring may be manufactured from a PTFE compound(e.g. Glass Fiber, PEEK) | FDA approved | -180°C to 260°C |

In house material compound capability and rich experience in PTFE filed can full fill your PTFE Teflon bellow project.

We offer on-demand manufacturing according to your actual order volume. No business too small.

We'll review your volume & design to determine a most cost-effective approach to yout PTFE bellow production from our in house PTFE compression molding and PTFE machining.

We have a wide range of materials so that everything can be customized as per your requirements with precision to produce high-quality components.

We provide free samples for you to make sure that you will get the precise and perfect parts for your business.

Being the leading PTFE bellows manufacturer provide excellent custom service specifically based on your needs with custom materials for high accuracy and precision.

We have extensive years of expertise with clients in various sectors as a competent machined parts manufacturer, and we can handle the various requirements of distinct industries.

Our quality management team ensures that the material, as well as the end product, are of top quality to serve you with the best.

Due to the high demands of chemical, mechanical, and thermal applications, PTFE bellows are manufactured by precise machining techniques and especially semi-finished material.