Custom Performance & Design

In house material compound capability and rich experience in PTFE filed can full fill your PTFE PEEK ball valve seats, PTFE ball and sphere needs.

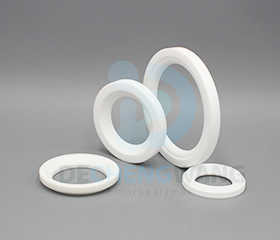

Seats and inserts, which are important components in the valve industry, as a critical component, PTFE is very often to choose as the raw material. PTFE provides a low friction seat, with excellent media compatibility. Filled grades provide wear resistance and can support seating loads of the higher class of valves.

Our strength lays in our people; our machine, and our ISO system control: 1) Over 13 years focus on PTFE filed, our machinists are Highly Experienced With PTFE Grade and machining skills. 2) We operate multiple, automatic, high speed and precision facilities(like Tsugami), a strong engineering team that guarantee both short-run and large production runs ; 3) All orders are manufactured to the ISO 9001 certified process control. Your orders are always Traceability.

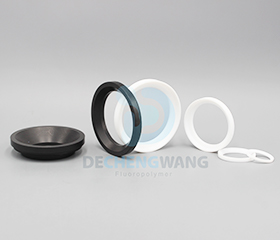

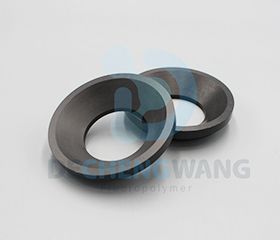

Carbon PTFE Compounds ball seat

PTFE ball valve seal

PTFE Ball valve seat

PTFE Ball

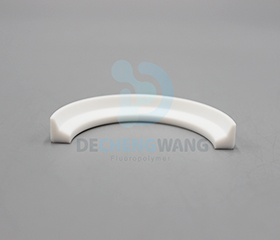

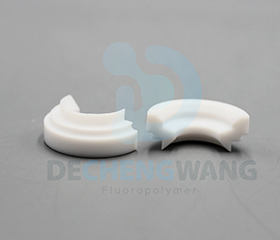

PTFE Seat 1

PTFE seat

PTFE Seats

PTFE sphere

PTFE valve seat

| Material Name | Compound % | Main Properties

Color |

Color |

| PTFE | / | Very low coefficient of friction and excellent chemical resistance.

FDA approved |

White |

| Glass Filled PTFE | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

| Carbon Filled PTFE | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

| Graphite Filled PTFE | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way.

|

Black |

| Bronze Filled PTFE | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance.

|

Dark Brown |

| Molybdenum disulphide(MoS2) Filled PTFE | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction.

|

Blue azure |

| PEEK Filled PTFE | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications.

|

Light Brown |

| PEEK | / | Excellent mechanical properties including strength, rigidity, impact resistance, low wear rate and low coefficient of friction, retained over a wide range of service temperatures | Light Brown |

| PEEK compound | / | Improves technical and chemical properties like deformation under load, wear resistance, thermal expansion and electrical conductivity. | / |

| PVDF | / | Resistant to UV radiation and offers high mechanical strength and abrasion resistance. | Beige |

| PCTFE | / | Better mechanical properties than other fluoropolymers, low permeability

|

Translucent |

| PFA | / | Excellent chemical and temperature resistance, electrical insulation and excellent processability | Natural |

In house material compound capability and rich experience in PTFE filed can full fill your PTFE PEEK ball valve seats, PTFE ball and sphere needs.

We offer on-demand manufacturing according to your actual order volume. No business too small.

We'll review your volume & design, to determine a most cost-effective approach to your PTFE seats from our in house PTFE compression molding and PTFE machining.

We have a diverse choice of materials, allowing us to precisely design everything to meet your specifications and make a high-quality PTFE/PEEK seat.

You may also get free samples of PTFE seat ball valve to ensure that you are engaging with the best supplier in the market and getting quality components.

As one of the top ball valve seat manufacturers, we provide great custom service with customized materials for high reliability and quality.

As a professional machined parts supplier, we have significant years of experience with clientele in different industries and can manage the varied expectations of different businesses.

Our quality management team guarantees that both the raw materials and the finished products like PTFE valve seats are of the highest quality in order to provide you with the best service possible.

PTFE ball valve seats are created using precise machining techniques and, in particular, semi-finished material because of the high requirements of chemical, mechanical, and thermal applications.

A ball valve seat is in charge of sealing the fluid inside and spreading the seating stress uniformly.

Our polymer ball valve seats help to distribute seating stress equally and are usually soft enough to adhere to the curve of the ball, resulting in a solid seal. Ball valve seats have a number of material needs in order to function properly.

The ball valve seat helps to distribute seating stress equally and is usually soft sufficient to adapt to the shape of the ball, resulting in a solid seal. To function properly, ball valve seats must meet a number of material specifications.

Low friction, adequate ductility to produce a dependable seal, good stress rebound, high stiffness, and great wear resistance are all essential features.

Ball valve seat materials must also be chemically resistant, have stable qualities even at extreme temperatures, have low water absorption, and have a very low coefficient of thermal expansion when used in important applications in harsh environments. Ball valve seats must be able to withstand extended exposure to hot water, steam, or possibly caustic cleaning agents in applications that need sterilization.

Due to its extremely low friction and high chemical compatibility across a wide range of chemical types, PTFE seats frequently rank towards the top of the list as a ball valve material. It comes in a variety of FDA-approved grades and is non-contaminating.

PTFE, PEEK, TFM, PCTFE, Acetal, Vespel, and other thermoplastics are commonly used for ball valve seats. We offer PTFE seats, PEEK seats according to your material selection.

Our PTFE Balls are ideal for commercial applications that need a neutral, corrosion-resistant sphere with the cleanliness, relative density, and excellent thermal stability spectrum that only PTFE can give.

Ball valves control the flow of fluid and pressure within a pipeline, but their effectiveness and safety are only as good as the seat material utilized.

Ball valve seats must be reliable and strong, whether used in a petrochemical application where a leak might be disastrous to the ecosystem or in a pharmaceutical facility where cleanliness and sanitation are vital.

A ball valve is made up of the valve’s body, body cap, stem, hollow ball, and spherical ball valve seat. We provide high-quality, certified, and FDA-approved PTFE balls to meet all your industry requirements and demands.

PTFE balls are utilized in chemical handling pumps, check valves, ball bearings for mild loads, volume displacement balls for chemical baths, and a variety of other purposes.